The changing landscape of English and Welsh wine.

Vitifruit Equipment has been providing machinery solutions and customer service to the vineyard and fruit industries in the UK for more than 25 years. Started in 1995 by David Sayell who was joined by Richard Witt in 2010, their activity has expanded in line with the growth in the UK wine sector.

Richard and David aim to help the customer to reduce production costs while increasing quality, yield and profitability with equipment that best suits their budget and specific location requirements.

“We are always sourcing new technology and products appropriate for viticulture and aim to provide a range of new machinery offering cutting edge technology for growers, so please look out for updates from us via email, on our website, on Facebook and Twitter,” said Richard.

“In the early days I worked with a few vineyards in Kent and could see that they weren’t using appropriate equipment,” said David Sayell.“My local vineyard at Penshurst was using small farm or amenity equipment in the vines, and I could see that it was inefficient having seen what vineyards were doing in the Mosel, Alsace and Champagne.”

Growing up on the family farm, studying agriculture at Cirencester and Plumpton College then working as a farm contractor for a number of years David retains a practical outdoor work life and has also managed a small local vineyard for over 20 years.

His experience and understanding of working with machinery in the field coupled with extensive research, visiting manufacturers on the continent, attending trade shows and building up strong relationships with suppliers has helped David to provide specialist vineyard equipment, concentrating on reliability and usability.

David said: “I wanted to find quality, reliable equipment which would do the job asked of it and wasn’t going to cause after sales problems with breakdowns and disgruntled customers.”

While the viticulture machinery market has changed a lot since David started in equipment sales in 1995, his key principles remain the same and in 2010, David joined forces with Richard Witt to establish Vitifruit Equipment and further expand the provision of quality equipment.

The transition to Vitifruit Equipment helped to focus the business and with Richard looking after the day-to-day running of the company, David is able to concentrate on advising customers and identifying the right machinery for their needs.

“We give a very personal touch with David dedicated to looking after customers,” said Richard Witt. “It is not just about selling, because ill-advised choices can actually make a job harder. If a machine doesn’t do the job it is needed for, you are back to square one. We provide meaningful advice and part of our service is to identify and supply the exact machine for the job in hand.”

Taking specialist requirements and budgets into consideration, David has tried to find at least two suppliers for most machines at varying price points and always encourages customers to try the machines before they buy.

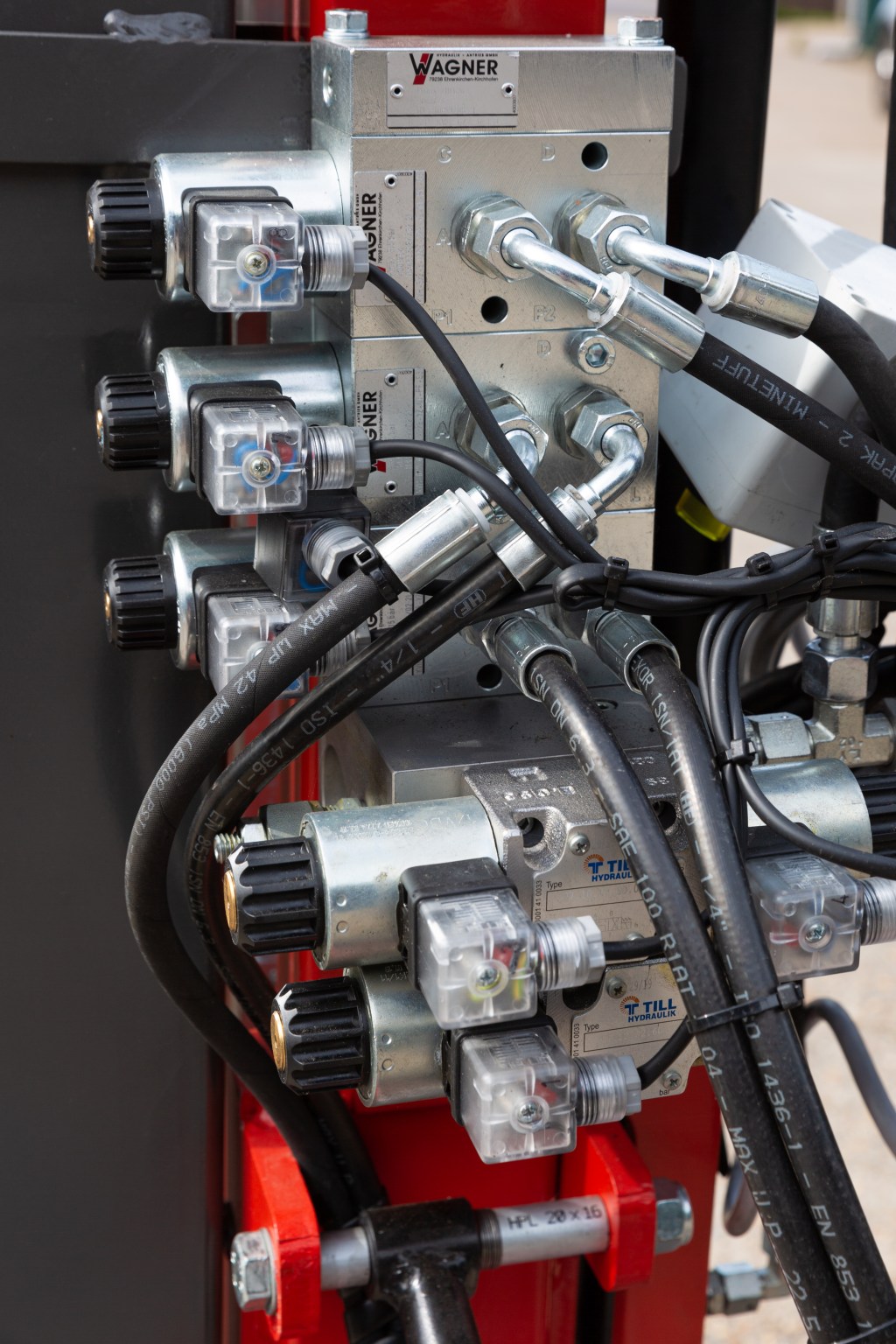

David said: “We don’t sell tractors as we don’t have a big workshop, however if a vineyard asks which tractor is right for them I will talk through their requirements, the size of the vineyard and the budget. As modern equipment relies so much on oil power it often comes down to the hydraulics of the tractor and finding a model which is comfortable and usable.”

Richard said: “We live in changing times and that affects vineyard operations. We have to alleviate labour issues. With the advent of Brexit, there are fewer workers from eastern Europe coming here. It has become a real issue finding the right people who have the know-how and practical experience and then retaining them!

David said that the sector is seriously lacking experienced tractor drivers and this puts us at a real disadvantage compared to other tooled up vineyards abroad who can produce a bottle of wine so much cheaper due to their efficiency. If we are to compete on price we have to train people who are competent machine operators and pay them accordingly.

Vitifruit Equipment has recently taken on Elihan ‘Han’ Rushanov who was with Chapel Down for five years as a principal tractor and machine operator and we have David Wood who looks after servicing, maintenance and repairs.”

With so many new players coming into English and Welsh wine, Richard and David are conscious that many will not have the knowledge, let alone the experience of, agricultural machinery. So, there are the twin challenges of: getting the necessary equipment and then, arguably even more crucial these days, finding someone with the relevant experience to operate it. “These people are like gold dust!” Said Richard.

Crucial to Vitifruit’s business is both hiring and selling equipment. David said: ”By hiring, it enables potential purchasers to have a go, a chance to try the equipment in the field.

“Much of the equipment we sell is for general vineyard maintenance but with the demand for more precision and record keeping, particularly with chemical use, the sales of higher specification sprayers has increased. Also more attention is being paid to the floor area under the vines in terms of weed control and soil care so we are very pleased with the results achieved over many years with the Boisselet equipment. An increase in activity with application of compost and manure means we now hire and sell a big range of spreaders, particularly since the recent hike in fertiliser prices.

David has been involved with WineGB/Plumpton roadshows which he believes have been immensely useful in bringing growers together to chat and exchange knowledge and experience. He showed various Vine Trimmers and De Leafers to assist the presentations on canopy management. Discussions ensued on everything from the practicalities of growing vines, dealing with/avoiding frost, disease management, leaf count, cordon styles, bud rubbing, leaf canopy density etc.

“The next few years should be seen as a challenge to bring the quality of UK wines up to world class standards, by investing in top quality people and equipment. We are busier and busier, helping more and more people,” said David.

Many vineyards are striving hard to increase their yield, tonnes per hectare, as well as the quality of grapes going into the winery. Attention to detail pays dividends concerning disease control, canopy management and under vine soil treatment. Machines go a long way to helping achieve the desired management objectives and the selection and use has become so much easier over the years as Vitifruit Equipment has listened to what growers want and responded by producing the kit.

- David Sayell, Richard Witt and Han Rushanov

This story was taken from the latest issue of Vineyard. For more up-to-date and in-depth reports for winemakers and growers in Great Britain, read our latest issue here and subscribe here.