In light of the large yields and abundant crop produced in 2023, and with the tirage and bottling season upon us, a frequent concern raised by wine producers, particularly traditional method sparkling winemakers, is the continual and growing need for suitable storage. Years such as 2018 and 2023 are great news for our thriving industry, with great PR and coverage in the press, and plenty of ripe grapes with which to make fantastic wine both still and sparkling. Whilst the ideal is to sell all of a vintage release within the year it is launched, the reality is more often than not an overlap between selling one vintage and bottling the current one. This situation is compounded for those businesses still growing where the volume of the earlier vintage they are selling is often far outstripped by the size of the current year’s production.

Storage of potentially five or more vintages at a time, particularly when growing your business, is an ever-present concern. The reality is sales budgets and targets are usually ambitious and often not met in the first few years as you grow your brand and customer base. This is compounded if you have any contract winemaking clients – you have zero control over their sales performance and they may well clog up your storage space for years if they are unable to turnover their stock fast enough. Likewise, if you are the contract client and the winery you are using finds itself severely restricted, you may see storage charges rise exponentially as they have to build or rent more space to fit the new vintage in.

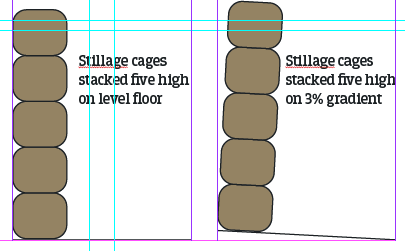

Wine stored in stillage cages, around 500 bottles per cage, can be stacked up to five cages high, where ceiling height (well over 5m to allow for manoeuvring) and forklift capacity (both for height and weight) allows. Each stack of cages has a footprint of around 1.2m2 and you need to have room within which the forklift can operate – usually around 4m of clear space, depending on the size and model. There are specialist forklifts that can work with smaller space constraints but they are usually more expensive and less versatile for other winery operations – they may also be unable to operate at the 5m height necessitating smaller stacks of three or four cages. It is worth also considering the added risk of stacking five cages high where you are unable to really see what you are doing with your forks and the fact that any incline or fall in the floor surface of your storage area will be hugely exaggerated at the height of 5m – see Figure 1.

Bottles stacked ‘sur lattes’ take up much less room but this requires some skill to perfect and adds a huge amount of extra labour to do so. The risk of collapse within the stacks and when removing bottles is increased, and once the wine is stacked it is not easy to move before riddling and disgorging if you need to.

Thanks to space constraints for many producers, off-site storage can look attractive. The option of a third-party warehouse with good security, great temperature and light control along with efficient and easy movements in and out as required can make all the difference to the viability of a winery in terms of both space and costs (compared to building a new warehouse yourself). Of course, it has to be bonded, and with the right type of Excise licence. There are many grey areas around third-party storage for wine stored by one producer on behalf of another, especially if the third-party winery neither made the wine nor will be disgorging it. Even more so if the wine to be stored is on cork already and there are no plans to fundamentally change the product status within the producer warehouse (i.e. disgorging). Even moving wine between two warehouses on your own land can fall foul of regulation. You must ensure that any new locations that are not immediately adjacent to one another (and even then it is best to check) are covered by your producer’s licence. If you use a third-party warehouse, it is even more important to ensure that all movements are tracked properly either by CAD (Commercial Accompanying Document) or Form W8, depending on status of the product being moved (grapes, bulk or finished wines). The HMRC Notice 163: Wine Production is the source of information you will need for making sure you adhere to the law.

As of July 2024, Carvers Hill Estate, a new vineyard business in Wiltshire, has anticipated the need for storage of wine on lees and as the finished product. They have built three separate and dedicated warehouses adjacent to their winery building. Taking advice from the outset, the storage warehouses are all temperature controlled and fully bonded, allowing them to accept wine in all states from producers in the UK and on behalf of merchants importing from other countries. The warehouses are equipped with racking for palletised wines as well as dedicated areas for stacking stillage cages. No windows and appropriate lighting along with solid steel doors and great security means producers and importers alike can store their wines safe in the knowledge that they will be secure. Ideal for long-term storage of wine to be aged on lees, the monthly fees will be very reasonable along with a simple structure for handling bulk receivals and dispatches.

Having worked in the English wine industry for close to 20 years, latterly as a consultant to many existing and new businesses, it is the most common problem a winery faces at some point, in fact, I don’t think there is a single winery business that hasn’t faced this problem and the associated costs. Carvers Hill Estate is anticipating both its own needs and those of the wider industry.

Figure 1: The lean or tilt of cages stacked five high on a level floor compared to 3% gradient. An incline on the floor will restrict how high you can safely stack the cages

Key points to consider when looking at storage

- Temperature – consistent (variation is the enemy of wine) and within the range 12-16°C

- Ultra-Violet light – either natural or artificial – can cause light strike and ruin the wine (particularly wine in clear glass)

- Security – wine is an attractive target, particularly when labelled and packaged

- Bonded – is the warehouse bonded with the correct Excise licences – absolutely key if the warehouse in question is offering third-party storage only – do not assume a Producer’s Licence is sufficient.If HMRC are not satisfied that the correct Excise Licence, or movement paperwork, is in place they can seize and destroy the goods and issue penalties that would kill most businesses.

One of England’s most respected winemakers, with a string of awards and trophies under her belt, Emma Rice is now working as an independent winemaking consultant to both new and established wine businesses in the UK. She has been at the forefront of our industry since 2008, heavily involved with WineGB, most recently as a Director on the Board. Co-author of The Wine Producers’ Handbook – a guide to setting up a vineyard and winery in the UK, she was also a major contributor to WineGB’s New Entrants’ Guide – a useful handbook issued to all new members. As a Liveryman of the Vintners Company she represents English winemaking to the wider trade and mentors young winemakers, through the Vintners Apprenticeship Scheme, which she initiated in 2016.