A conversation at the 2021 Vineyard & Winery Show organised by Vineyard magazine was the catalyst for a new business that has begun offering a full supply and installation service to wineries across the UK.

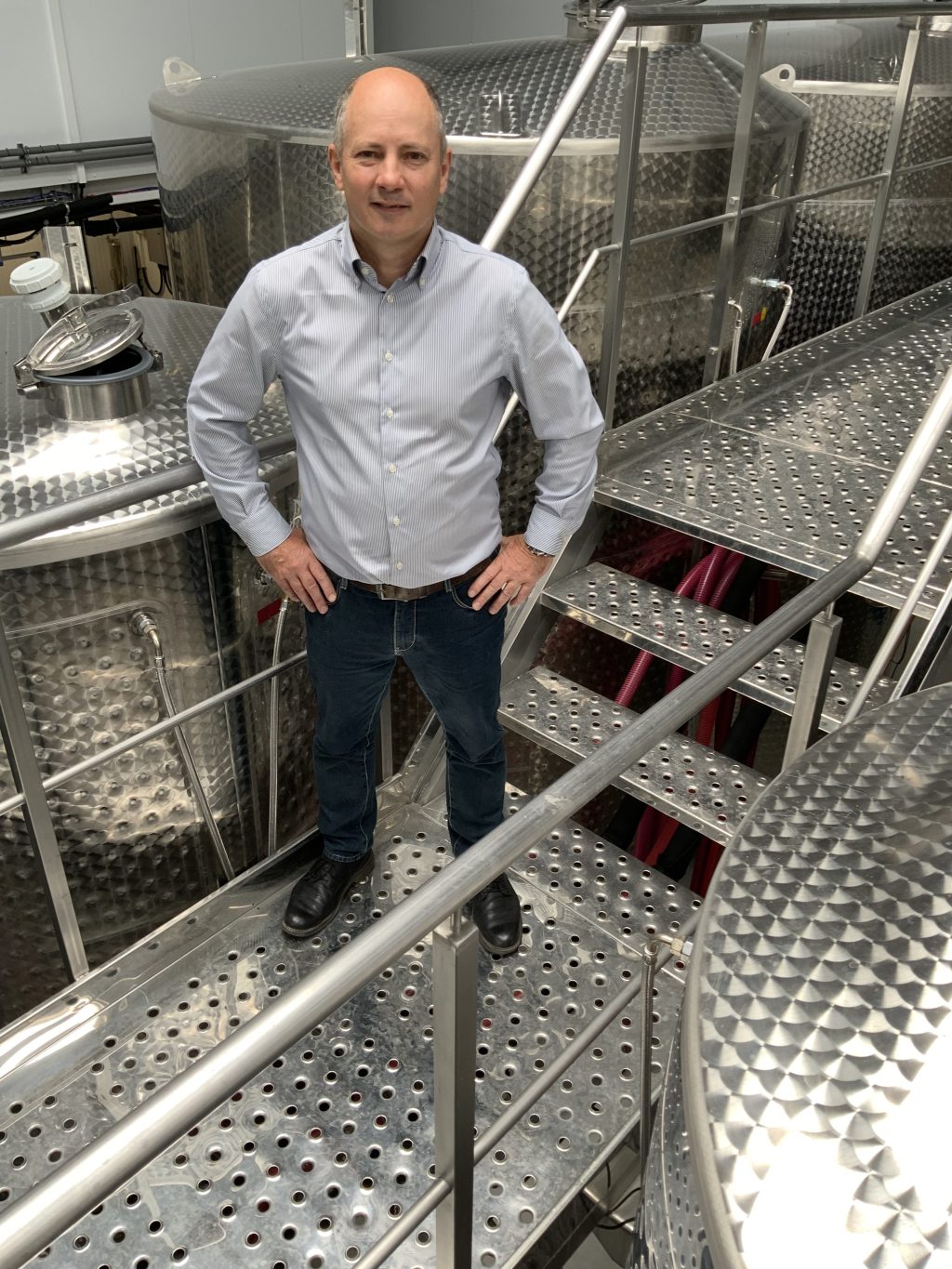

Itasca Technical Services is a new division of Itasca Wines, set up by owner Malcolm Walker and being taken forward by Sales Director John Simmons, a hugely experienced and well-known figure in the industry.

The business can provide and install everything a winery needs, from tanks and presses, agitators, filters and pumps to bottling and labelling equipment, additives and chemicals.

With the customer database already growing swiftly, Malcolm Walker is convinced that the industry was ready for a new, client-focused link between supplier and customer.

“Interestingly, as soon as we set up Itasca Technical Services we were approached by a number of manufacturers and suppliers who wanted us to represent them also,” he said. Those companies include Enartis, Steroglass and Oculyze, all of which were keen to be showcased by Itasca’s up-and-coming new division.

The story began after Malcolm spent £1.5m fitting out the winery at the Penn Croft Vineyard at Crondall on the Surrey/Hampshire border. Not keen on using the same supplier when he decided to invest in an eight-tonne press costing another £180,000, he met up with representatives from German manufacturer Scharfenberger at The Vineyard & Winery Show.

Malcolm found himself invited to Germany for a visit to the plant and some serious discussions about how they could work together. It resulted in the German company suggesting that if Itasca Wines was interested in setting up a distribution company, Scharfenberger would give the business the sole UK import licence.

What’s in a name?

Scharfenberger also, although inadvertently, named the UK company. “We were going to call it Itasca Engineering, but we received a letter from Germany addressed to Itasca Technical Services, and we thought it sounded so good that we used it from then on,” Malcolm admitted.

Malcolm then got in touch with John Simmons, well known in the industry and coincidentally living just a few miles from the Penn Croft vineyard home of Itasca Wines. Again, the two men bonded over a common goal of delivering great service to winemakers across the country, and so John came on board.

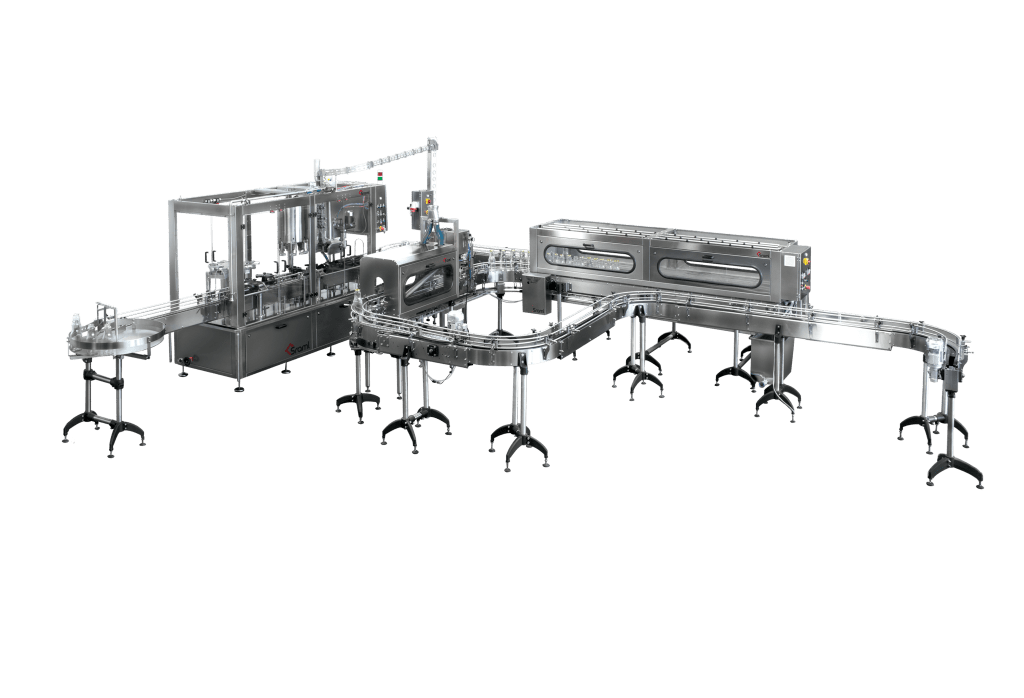

John is clear about what he believes Itasca Technical Services can deliver. “We can provide all the technical and manufacturing equipment for winemaking, from receiving the grapes through to processing them and then bottling the wine – or canning it, if wineries are looking to go down that route.

“Along with the kit – presses, agitators, filters, pumps disgorging equipment, yeast, chemicals and all the other things winemakers need – we see ourselves as offering a sympathetic, friendly ear, particularly for newcomers who are looking for advice as well as equipment.

“And we won’t walk away when the job is done, either. After-sales care is incredibly important to us and we know it’s top of the list for our customers, too.”

Itasca Technical Services then negotiated a UK import agreement with Sraml, the Slovenia-based food processing equipment supplier and specialist in the manufacture of wine equipment and juice and cider-making products, including reception equipment, destemmers and crushers, pumps, presses and bottling lines.

“Visiting Sraml in Slovenia was a fantastic experience,” said Malcolm. “To see such a well-organised and pristine factory in a stunning valley surrounded by vineyards was a privilege, the owners really looked after us and we had some stunning Slovenian wines, some of which Itasca Wines is now going to import into the UK.

“Itasca Technical Services is really looking forward to working with Sraml and their dynamic team.”

As the company picked up momentum, it was other companies getting in contact with Malcolm and his team, rather than the other way round. Enartis, which Itasca already represented in the UK and which provides yeast products and stabilisers, along with other chemicals, was joined by Steroglass, which provides laboratory equipment, wine analysers and other equipment.

Also part of the Itasca Technical Services stable is Oculyze, which produces a yeast cell counting kit that uses a mobile phone app to monitor yeast growth, and filtration product specialists Profil Solutions Ltd.

New supplier with benefits

When Malcolm tried to buy 26 more fermentation tanks direct from Latina, the company that had supplied the original Penn Croft winery, he was turned down. Instead he had to look elsewhere, in a move that may well turn out to have an additional benefit.

“We went to South Africa and are having our own new tanks built in Cape Town by Saturn Stainless Industries,” he said. “We followed that up by negotiating for Itasca Technical Services to be appointed the sole UK and European importer for Saturn, which has an impressive reputation internationally.

“The other benefit is that while there is a worldwide shortage of stainless steel, it seems to have hit Europe particularly hard, which means South Africa may well prove to be a more reliable source for tanks, at least in the short to medium term.”

After what Malcolm described as “a whirlwind few months touring factories and meeting people”, Itasca Technical Services hit the ground running. With a number of orders already confirmed, including for a bottling line and elevators, the division is working hard to close a potential order for an entire winery. “Given what we have created here at Penn Croft, we can even build the winery itself, if necessary,” he added.

Itasca Technical Services is going beyond supplying and installing equipment and will deliver the most comprehensive service possible. “The company has won a service contract to provide a maintenance and breakdown service to existing customers of a large manufacturer,” Malcolm explained.

To do that, Itasca Technical Services is partnering with a Reading-based engineering company and is working with Itasca’s suppliers to train two specific engineers who will be on call and ready to deal with incidents anywhere in the country

“These fully trained and dedicated engineers will be available 24/7 to support existing customers as well as providing after-sales service on new installations carried out by our team,” Malcolm said.

Itasca Technical Services will also hold a stock of the parts that are most usually involved in breakdowns, with a particular focus on making sure harvest is not interrupted for any longer than is absolutely necessary.

It’s happened before

The success of Itasca Technical Services, which has seen potential suppliers approaching Malcolm rather than the other way round, is not an unusual experience for him and his team.

While he talks about being “lucky”, it’s difficult to avoid the conclusion that he’s a man who makes his own luck. He may have been “at the right place at the right time”, but his enthusiasm, his dedication and his determination to succeed shine through.

Malcolm originally planted the vines at Penn Croft Farms in partnership with farmer and landowner Simon Porter so that he could film the venture as a follow up to his Cellar Rats TV series. Simon had become his landlord when Malcolm relocated his independent production company, Itasca Films, to the site some 11 years ago.

The chance conversation about the possibility of planting vines at Penn Croft led to what the two men have since described as “one of those life-changing events which just falls into place without having to try too hard” and resulted in Itasca Wines and Penn Croft Vineyard becoming a reality.

After planting vines on what had been a wheat field, Itasca Wines built a winery to turn the Penn Croft grapes into wine, and soon found themselves in demand.

An article in Vineyard magazine about Malcolm the film Producer and Simon the regenerative farmer set the ball rolling. “One well-known vineyard rang to ask about renting storage space and then we had enquiries from other growers asking if we would make wine from their grapes. We soon found out that with far more vineyards than wineries in the south east there was a real opportunity for quality winemakers,” explained the filmmaker turned winemaker.

“Part of the problem was that some of the original wineries that had offered contract winemaking were steadily harvesting more and more of their own grapes and were running out of capacity to support other growers, which created demand we were able to meet.

“We have been exceedingly lucky that people phoned us. A lot of where we’ve got to was not planned but has come from organic growth as a result of other people’s enquiries.” It’s a modest statement, and one that ignores the commitment and drive demonstrated by Malcolm, Penn Croft winemaker Ben Smith and the rest of the team – now joined by the Itasca Technical Services division.

Itasca Wines is set to process 400 tonnes of grapes this year and has a capacity of 600 tonnes – a figure that may be expanded in the future to 1,000 tonnes. The winery makes and labels wines on behalf of 20 vineyards across the south east from Exeter to Essex, and while the region remains best known for its fizz, Itasca is increasingly making still white wines.

“The other benefit we have here is that the winery acts as a showroom for the equipment we sell,” John added. “Customers can come here, chat to us about what we need and potentially see it in action, too.”

Ben’s expertise saw the winery pick up three silver medals in the Wine GB 2021 awards. They went to Penn Croft’s Bacchus 2021 and Pinot Blanc 2021 and the Sauvignon Blanc made for Essex vineyard Missing Gate.

- John Simmons