How oxygen management influences all sensory attributes of the wine.

Oxidation and reduction characters in wine are the leading wine faults detected at wine competitions. Many factors are at play when managing oxygen during the winemaking process, from must treatment, filtration, storage and bottling being the critical point. Having the tools to manage oxygen such as inerting and gas sparging systems, appropriate valves and pumps as well as fining and stabilising agents to manage phenolics which are one of the main sources of oxidative character in wine.

Phenolics react with oxygen to produce quinones which can lead to acetaldehyde creation from Ethanol. Oxidation reactions also contribute to browning or discolouration of wine and ultimately dull the aromatic components, especially Thiol groups. SO2, ascorbic acid and glutathione are wine ingredients used to protect from oxidation as are tannins, either toasted or untoasted, that provide anti-oxidative properties to wine.

The risks factors from oxygen is high on the list to the winemaker but it is important not to fully demonise oxygen. It is a critical element that is needed during the fermentation process, managing grape must before fermentation as well as combating reductive wine parameters such as Hydrogen Sulphite. The ability to measure oxygen (Head space + Dissolved Oxygen (DO)) that give Total Package Oxygen (TPO) as well as managing phenolic content through fining trials and tannin additions is critical. As is proper gas management and inertion of tanks and most importantly the bottling process.

Inerting practices

Nitrogen is perceived as the best method of inerting and does not react with the wine but is lighter than air so blanketing with N is not the best choice. Carbon dioxide on the other hand is preferred as it is heavier than air and can act as a barrier between wine and the atmosphere, although correct sparging is critical due to gas turbulence and CO2 dissolves readily in wine. Argon is the best of both worlds but is more expensive. At bottling is important to inert the bottle as well as the screw cap in a controlled and measurable way. Auditing the bottling operations is an important part of good quality management as is checking oxygen levels. This is a service we offer our customers and can arrange this with the Bruni Erben team.

Checking oxygen levels

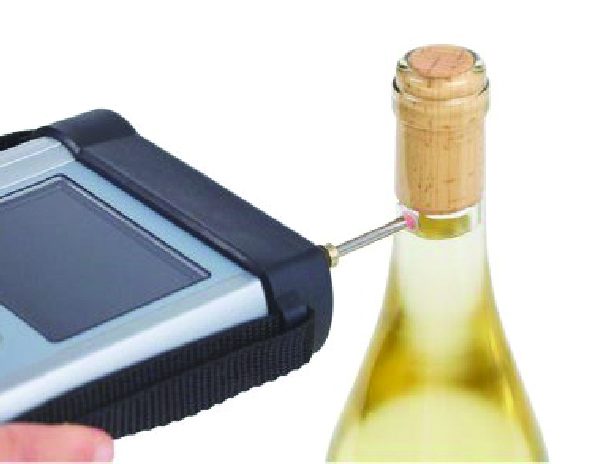

NomaSense O2 analyser allows winemakers to measure oxygen levels thanks to a technology based on luminescence, combined with the use of remote sensors, the portable device measures oxygen dissolved in wine and in gas phases. Oxygen can be measured at every stage of the wine’s lifecycle, in particular during the packaging process, this allows real-time analysis. Machine settings can then be adjusted to achieve the lowest TPO possible during bottling.

- Check the consistency of filling and corking heads on a bottling line

- Reduce variations in bottling performance between the beginning and the end of the process, limiting the difference between one bottle to the next

- Identification of the critical oxygen pick-up stages throughout the winemaking process

- Implementation of supervised strategies to reduce levels of SO2

- Implementation of inerting procedures to maintain quality and reduce costs.

Fining agent and Tannin additions

It is important to perform bench trials, 500ml beer bottles with swing stoppers often provide a very good format for bench trials if an Imhoff Funnel isn’t readily available. Laffort have a comprehensive range of fining agents to treat grape must and finished wine to assist in the wine making process. Casein based fining agents such as Casein plus, are effective in combat browning and bitterness in finished wine. Plant based fining agents such as Vegecoll have also seen good results and are carry less risk of over-fining. Tannin additions on the other hand can be added to finished wine to enhance organoleptic properties as well as providing effective oxygen protection.

There are many routes to check and manage oxygen and being aware of the pitfalls and processes to manage O2 can give the winemaker a greater control in producing the specific wine style. For further information and services and products on offer please contact mark@erben.co.uk or telephone 07805018677, also check out www.erben.co.uk for further products and technical insights and future events.