Part 1: Total Package Oxygen (TPO) and the importance of headspace oxygen

• www.BruniErben.co.uk • Mark.Crumpton@BruniErben.co.uk • 07805 081677

In today’s rapid turnaround market, there is a growing interest towards winemaking practices that are able to give wines that are ready for drinking when they leave the production facility. However, even with these fast turnaround times, a period of several weeks or even months intervene typically between bottling and consumption of wine, during which wine sensory characteristics can change as a result of the different chemical reactions taking place. Overall, it is often said that wine reaches a balance after some time in the bottle, provided that adequate conditions exist, including having appropriate levels of oxygen.

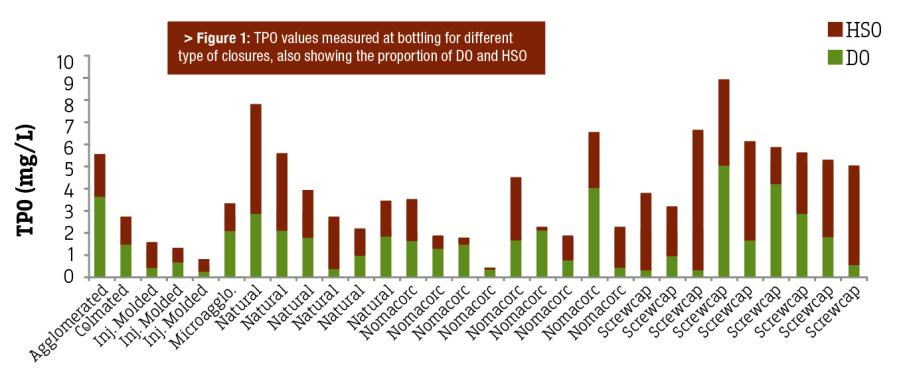

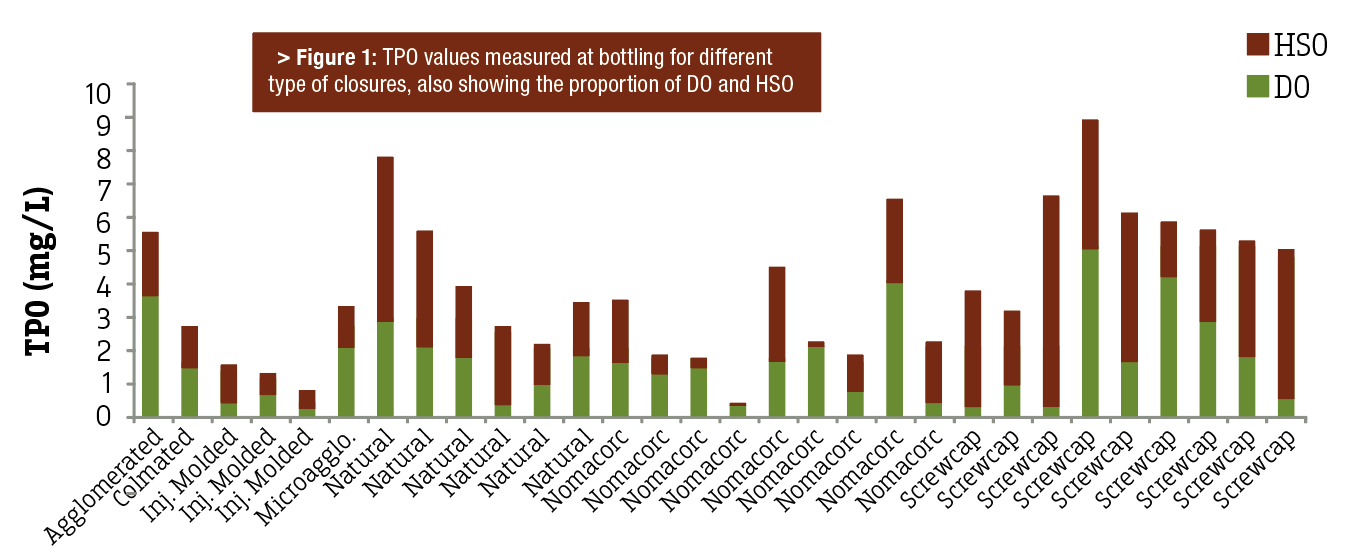

The type of closure, and specifically its OTR (oxygen transmission rate) value is certainly a major factor contributing to oxygen exposure in the bottle. However, although very important, closure OTR is not the only factor influencing wine exposure to oxygen inside a sealed bottle. Figure 1 shows a set of data collected at different wineries by means of the oxo-luminescence-based Nomasense® oxygen analyzer, during bottling sessions using different bottling equipment and closure types. As it can be seen, the amount of oxygen present at bottling, typically referred to as TPO (total package oxygen), can consist of several mg/L, in some cases reaching values close to 10 mg/L. Considering that closures currently existing on the market cover a rage of approximately 0.55 mg O2/bottle/year, these values are equivalent to the amount of oxygen that will permeate through a closure over several years. It can be therefore deduced that TPO represents a highly significant component of the oxygen seen by a finished wine in its entire life. The following is aimed at showing the influence of TPO on wine evolution, illustrating how correct management of TPO is a key ingredient to achieve consistent post-bottling evolution.

Dissolved and headspace: the components of TPO

Figure 1 also shows, for each of the TPO measures taken, the split between dissolved oxygen (DO) and headspace oxygen (HSO). While DO is often higher than HSO, this cannot be generalized, as several instances were found where, in spite of a low DO, TPO was still high due to high HSO. This is of great interest, given that most wineries tend to rely on DO measures to assess their overall ability to keep oxygen under control. While this is correct for monitoring of oxygen exposure throughout the winemaking process, when it comes to bottling performances the measurement of DO alone is obviously not sufficient anymore, and HSO should be taken into account.

From the data in Figure 1 it can be observed that too high TPO values can be common to all closure types, regardless of whether they are cylindrical (e.g. natural cork, agglomerated cork, synthetic co-extruded, injected molded) or screw cap. TPO values are linked to good conditions of storage and handling of the wine to minimize DO pickup prior to bottling, as well as to optimal functioning of inerting equipment at bottling. It seems therefore logical that the type of closure has a secondary influence on TPO. However, a trend seems to exist in this dataset, with screw caps always being affected by relatively higher HSO (average HSO for screw cap 3.66 mg/L, compared to 1.54 mg/L for other cylindrical and 1.27 mg/L for Nomacorc). This reflects probably the fact that, in screw capped bottles, headspace volume is much larger, and oxygen is more difficult to remove. Additionally, the air trapped under the screw cap can be conveyed back into the bottleneck upon application of the cap, further contributing to higher HSO.

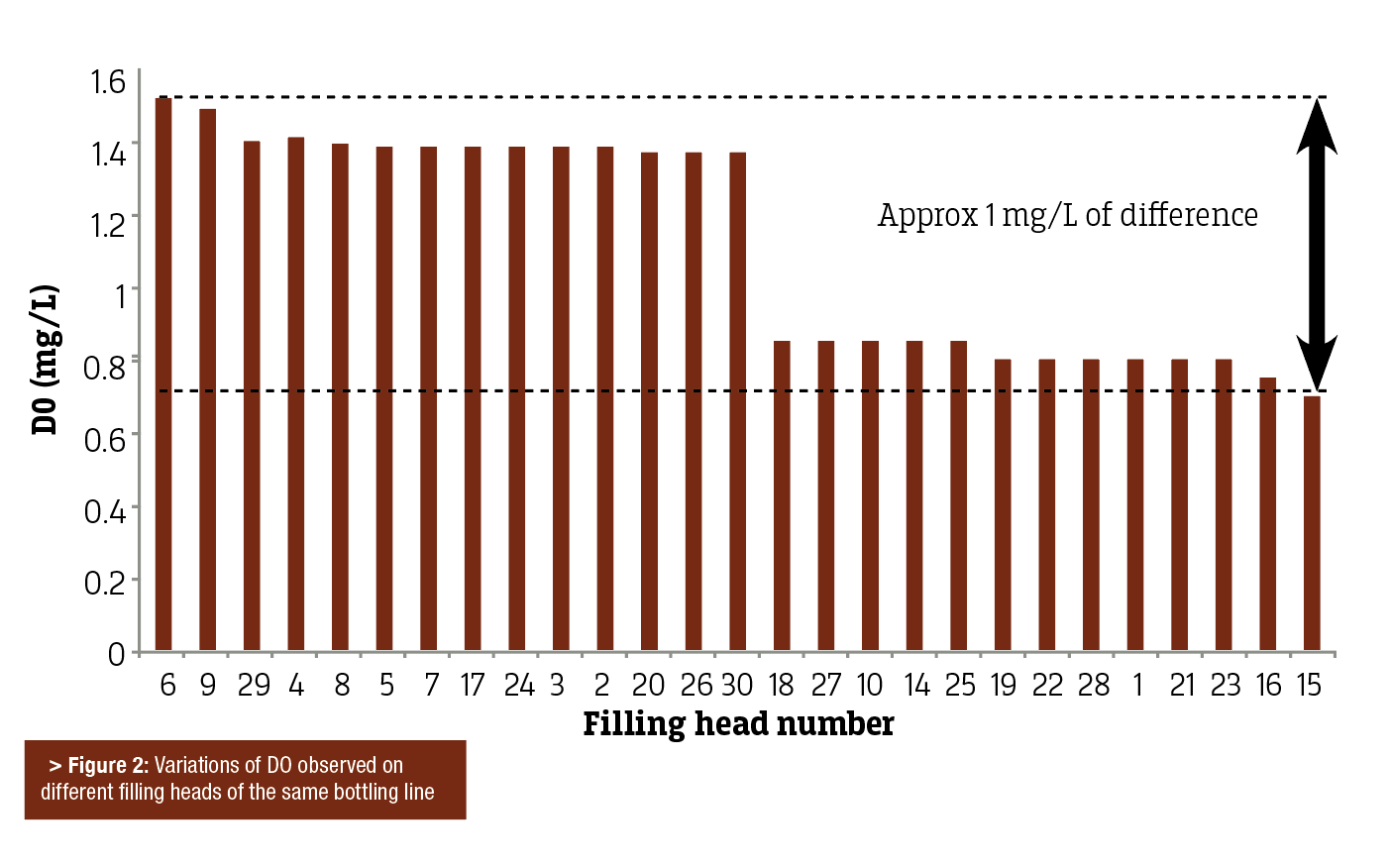

From a practical point of view, excessive DO or HSO levels, although part of the same problem, have very different origins and require very different cures. Leaving aside issues of high DO related to inadequate storage and transfer conditions, DO levels in the bottle can often reflect oxygen pickup during bottling operation, for example at the level of individual filler heads. This can be the source of a relatively high variation in TPO at bottling, as can be observed in Figure 2.

Conversely, HSO values are linked to the performance of the inerting devices that are active on a bottling line (e.g. nitrogen sparging, vacuum, etc). Malfunctioning of these devices can be rather common, but it is difficult to assess as it requires measuring the oxygen concentration in the headspace of a sealed bottle.

Bruni Erben can supply the complete range of closures to suit your needs and bottling requirements as well as the machinery and support to ensure precise and consistent bottling.

Read part 2 in the next issue