The crop protection specialists proudly supporting vineyards across the entire UK.

Since being founded in 1938, crop production specialists Hutchinsons has grown from an operation serving fruit growers in the Wisbech area of Cambridgeshire, to one of the nation’s leading agricultural and horticultural input advice and supply companies.

Today, brothers David and Mike Hutchinson continue to play an active role in the family-owned business which celebrated its 80th anniversary last year. Driven by a modern, forward-thinking approach, the Hutchinsons and their dedicated, 450-strong team are committed to providing the best agronomy and crop protection advice, products and services to growers of all crops across the entire UK, from Aberdeen to Truro.

Well-known for its unfaltering support of even the most rarely planted and emerging crops types, Hutchinsons is a leading light in the UK’s flourishing viticultural scene, with its specialist agronomists advising vineyards of all sizes, on all aspects of grape growing from site selection to strategic pest and disease management programmes.

With a busy sundries department, Hutchinsons is also able to provide vineyard managers with a range of essentials and, to complete the grape to glass journey, sister company, Producing Packaging, is also on hand with its extensive box-making expertise to ensure that English and Welsh wines reach consumers in the most pristine conditions.

Expanding plantings

Grapes are not a new crop for Hutchinsons, and in fact the team is now proud to be building relationships with many second-generation viticulturists. Chris Cooper, Hutchinsons’ agronomist looking after growers in the South and West regions, remembers dabbling with home-made wine and ‘popping up the valley’ in Devon in the 1980s to talk about viticulture with Gillian Pearkes, one of the doyennes of UK viticulture.

There has, however, been a tremendous change in the sector in the last few years. Focus has shifted from producing still whites with Germanic varietals to traditional method sparkling with the classic trio. Growing systems are different, technology is more advanced, and the management is better informed with many having studied on viticultural courses and workshops.

Most notable within this evolution is the expanding area under vine, which has increased by 82% since 2015. By comparison to the 3.9 million hectares of arable crops grown in England in 2019, the UK’s 3,000 hectares of vines might seem just a tiny drop in a very large agricultural ocean, but for the horticultural team at Hutchinsons grapes continue to be one of the firm’s most interesting and valued crops.

“It is very exciting to see so many people planting vines and starting their journey into the viticulture sector,” said Mike Hutchinson, horticulture director at Hutchinsons. “We want to be the number one provider of agronomy, inputs and services to the vineyard sector. We have always been passionate about working with niche crops and consider ourselves to already be in that position with other minor crops, such as blackcurrants and hops. Regardless of whether there are hundreds, or thousands of acres planted, all growers are extremely important to us.”

With the expansion of plantings testament to the popularity and interest surrounding English and Welsh wines, the distance between neighbouring sites is undoubtedly shrinking and once isolated growers have started to notice increasing disease and pest pressures.

“Vines are currently following a similar pattern to blueberries which took off very rapidly in the UK about 10 years ago,” said Mike. “When a crop is planted initially, there is almost a pest and disease holiday because there are hundreds of miles between sites. As we progress to several million vines in the ground, diseases inevitably find it easier to spread. It also becomes more challenging to contain pests, such as Light Brown Apple Moth or European Vine Moth. Nature is very unpredictable. Everyone is learning together, and our team is here to help vineyard owners and managers to understand how to grow and better protect their grapes.”

Adopting a vigilant approach to crop monitoring and protection is vital to ensuring that fruit survives in top quality condition right up until harvest. Whether novice or expert, having the support of a skilled and specialist agronomist, who not only knows your site but who also has a real-time overview of pest and disease pressures in the surrounding region, is invaluable.

What is good agronomy?

It is a myth that you can plant a vineyard on a commercial scale and, left to its own devices, it will grow and thrive. It is also a myth that agronomists are a second line of defence; someone to call after the problems have started appearing. Good agronomy really starts before the vines have even been grafted.

“Site selection is vital for the long-term success and, more importantly, viability of the enterprise,” said Rob. “We have advised countless fruit growers on whether sites are suitable for vines, but for some reason people coming into viticulture from other careers, don’t always think to approach an agronomist first. We would prefer to start talking to clients before they have a crop in the ground because we will have a good idea of the local region and the individual issues they are likely to experience on their estate.”

As well as having a good eye for the land, the team at Hutchinsons can also advise on which varietals are likely to match the site, the growers’ capabilities and any end product expectations.

“If you have your heart set on making traditional method sparkling with the Champagne trio, then you need to be aware that the Pinots are more susceptible to mildew than hybrid varieties,” said Chris Cooper. “Having said that, a grower cannot simply choose varieties like Solaris or Rondo just because they are more robust and less disease prone. You need to consider what wine you are trying to make, where this will be sold and what style your target market will be open to. If you decide you need to grow a more susceptible cultivar to produce the right wines, then you should be willing to do everything possible to control the diseases, or risk losing the crop.”

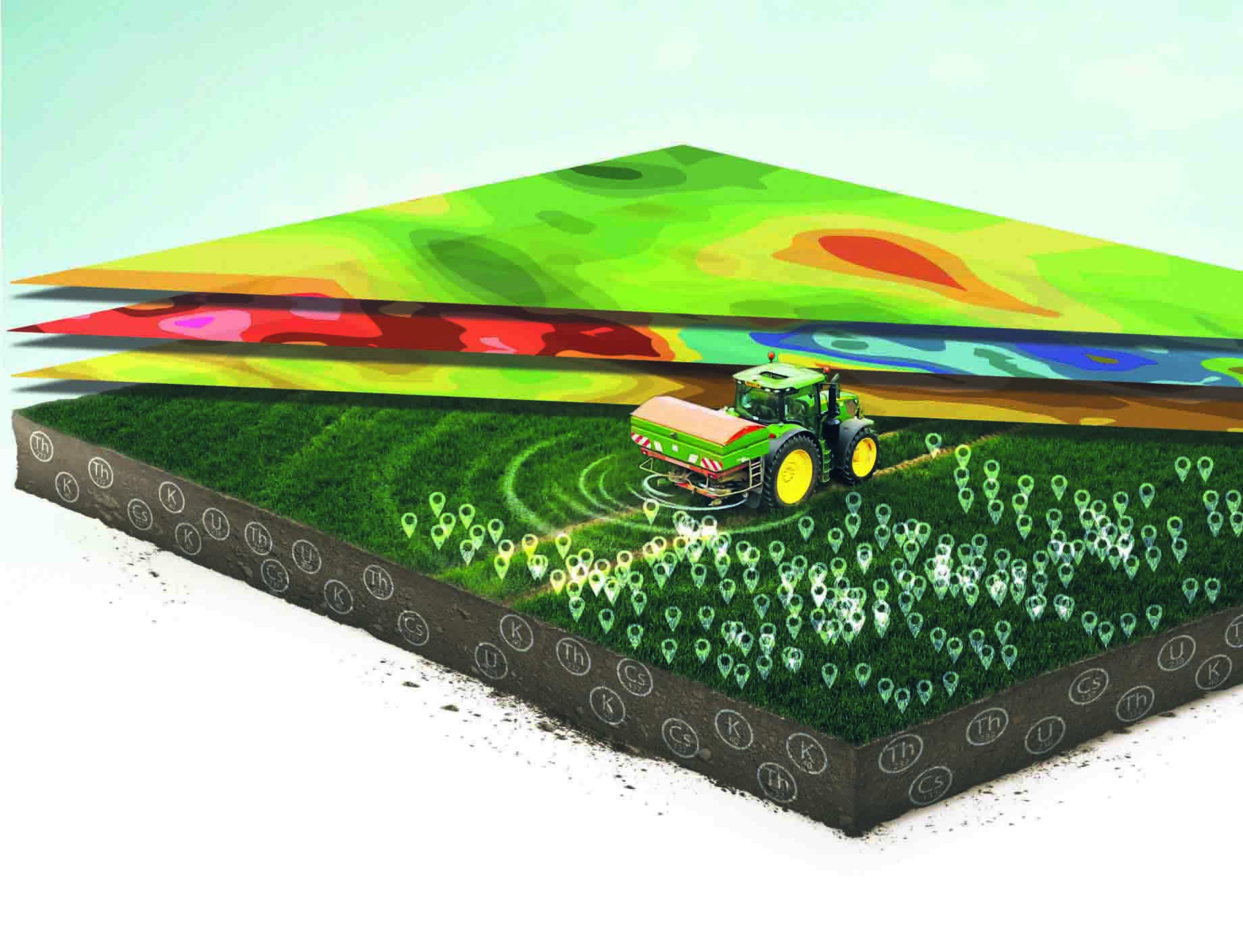

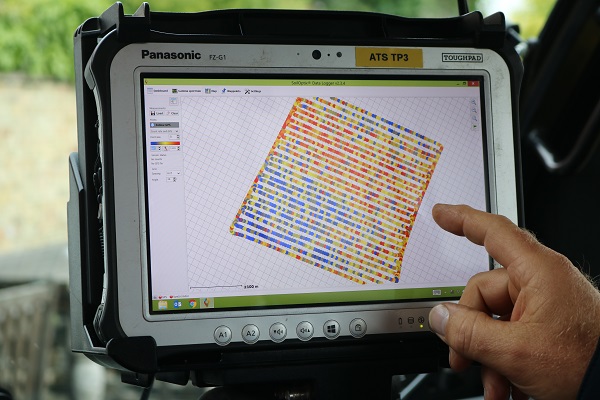

For those preparing to plant a vineyard, this summer Hutchinsons launched a new soil mapping service called TerraMap. This high definition soil scanning system is capable of recording over 800 data points per hectare to produce over 21 different field layers. The machine measures naturally-emitting gamma radiation from the soil to calculate all common nutrient properties, pH, soil texture, organic matter and CEC as well as elevation and plant available water.

“This new technology allows growers to thoroughly understand sites and soils before planting,” said Mike. “By linking this data to our Omnia platform, agronomists and growers can make the most of precision technology, such as variable rate spreaders which will apply very specific amounts of fertiliser in exactly the right place. It is about optimising your inputs and ensuring that the land is well balanced before you even plant the vines.”

The TerraMap system can also be used in an already established vineyard to monitor the soil’s changing nutritional status over time and it is also useful in solving previously unexplained factors, for instance if there is a peculiar corner in a vineyard where the vines aren’t growing or are struggling.

Once planted, it is advisable that anyone who has established over an acre has some formal viticultural training with an education provider to ensure that they have a good idea of what basic diseases and pest damage look like. Recently, Chris and Rob have also helped membership organisation WineGB to produce a booklet of common diseases which can be used in the field.

“If growers have a good idea of what pest or disease they might be up against, then it is just a case of asking the right people how to deal with it,” said Chris.

What is a good agronomist?

One of the defining features of Hutchinsons’ viticultural offering is the team’s knowledge across a range of crops and an unmatched level of communication, both between agronomists and with their growers.

After developing an interest in vines while studying applied biology and crop protection, Chris Cooper moved to Kent where he shadowed the viticultural specialist at Heath Horticulture until they retired and Chris took on that mantle. Chris joined Hutchinsons in the early 2000s, moving back to the West Country to service growers in that region.

While in Kent, Chris lived just a few hundred yards away from Rob Saunders, who was an assistant manager of a fruit farm at the time. They became friends and Chris introduced Rob to the idea of becoming an agronomist. Rob spent several years working as an agronomist in Kent, where he first became involved in viticulture in a small way, before an opportunity came up to join GlaxoSmithKline to look after the blackcurrants for Ribena. After the brand was sold to another company Rob decided to join Hutchinsons and has been taking a special interest in the viticultural scene since 2014.

“There are many interesting parallels between blackcurrants and grapes,” said Rob. “Both crops share a public enemy number one, botrytis; if you put on too much nitrogen the party is over; and the key aim is to make a good drink at the end. Richard Smart had it right when he titled his book ‘Sunlight into Wine’ and in both crops you are trying to manage a canopy to capture enough sunlight to get good sugar levels.”

Managing the canopy throughout the season can be particularly tricky in the UK, where sites are often much wetter than other traditional grape growing regions and where fertile soils promote overly vigorous vines.

“As well as keeping the canopy in an excellent condition, growers will also need to manage the vines in such a way as to keep botrytis at bay while fruit is still ripening into October,” said Rob. “It is a significant challenge because, by definition, a cool climate wine is one where the grapes are ripening at the same time as the canopy is declining. This is why so many winemakers say that wine is really made in the vineyard.”

As well as being able to draw on his 14 years’ experience in blackcurrants, Rob heads up an Innovative Farmers hop soils project, which focuses on improving soil health and looking at how soil health can be improved with winter cover cropping, and as the chair of the AHDB tree fruit panel he has been involved in extensive research into SWD in cherries.

“We have learnt a lot by looking at cherries as a lead crop and I have been able to apply this knowledge to grapes,” said Rob. “For instance, we found that red traps are more attractive to SWD, so it is easy to see why red grapes are more at risk. Then by looking at the cherry varieties which are favoured by the females, which saw a hole in the skin to lay eggs, it becomes clear that grapes with thin skins will be more at risk than those with thicker ones.”

Alongside Rob, the entire team at Hutchinsons, continue to work across other similar crops, such as hops, allowing for a powerful cross fertilisation of ideas and the ability to adapt protection principles from one crop to another.

“We have enough of an involvement in viticulture to know the industry inside and out, but having a wider horticultural view and previous experience of managing canopies and botrytis on an industrial scale is very beneficial,” said Rob. “Chris is also very knowledgeable when it comes to products and approvals and he is incredibly skilled at looking at what might be working well on other crops and applying them to vines. For instance, if there is something particularly effective in fighting downy mildew in hops, we can see if it will also apply to vines.”

This wider understanding is further strengthened and utilised as knowledge is continuously shared between members of the team via a very active group discussion where photographs of key phenological stages, diseases, pests and weeds, along with new ideas and questions are exchanged on an almost daily basis.

“Each grower has access to their own agronomist and we are there to develop a one to one relationship,” said Chris, “but when we arrive at the vineyard, the grower is also tapping into a much larger bank of information and experience. It is impossible for any one person to know everything about a crop and this sharing ethos is a real strength for the entire Hutchinsons horticultural division.”

Pooling the team’s experiences is also a good way to break down geographical boundaries as Chris covers North Wales to South Cornwall, Rob covers the South East and John Chapman looks after growers across East Anglia.

“Problems often migrate and for the vineyards which might be very isolated, if their agronomist is aware of what’s happening elsewhere, it is possible to get a head start on issues,” said Mike Hutchinson. “If everyone else has already started thinking about strategies, you can have the radar on the pest or disease and when it does get to you, you will have the benefit of learning from other vineyards via your agronomist.”

As well as keeping in touch with each other, every month the Hutchinsons viticulture team write an essential agronomy diary for Vineyard Magazine to keep growers abreast of what’s changing and what’s going on. During the growing season, the team also produce a newsletter which is sent out to current customers. In this, Chris, Rob and John discuss what has been seen, as well as what growers should be expecting to see, and overall advice for how to mitigate and overcome any potential problems.

Services for growers

On a most basic level, the viticulture team at Hutchinsons provide its growers with advice on pests, disease and nutrition, and prescribe relevant products which can help solve issues and protect fruit. However, there is far more to it than that.

“We are here to provide our growers with an overview and a real-time intelligence into what is going on with the crop in their vineyard and the wider area,” said Rob. “Then we can provide a strategic view and suggest what is the best way to deploy the tools available to the grower. A lot of that is esoteric and there are not many people the grower can have a sensible conversation with about the right sequence in which to go about something to get the best results. Although vineyard managers should have a good understanding of what they need to do next in the vineyard, it is often useful for them, to talk about what they are up to and so we also act as a bit of a sounding board.”

As different growers have different needs, the number and frequency of on-site visits will vary drastically. Those who are growing on a commercial scale and rely on that crop to make a living, may see someone on a fortnightly basis, while those who understand what the relevant diseases and pest damage looks like might not need someone to come out that often, but will need occasional help with strategy and benefit from catching up with someone who has a more regional insight.

The team is also there to share understanding and knowledge about current legislation, product status and any changes. It is very easy for growers operating in a vacuum to try and implement the same regime or spray programme as last year, but a product might no longer be approved, or there might be something else now available which is stronger or has a better anti resistant strategy and a good agronomist can advise on this.

Future of chemicals

No one is more skilled on this topic than Chris Cooper. In support of the wider industry, Chris is a member of the WineGB viticulture advisory working group, and is also the membership organisation’s technical support officer, looking after its ‘Green Book’ resource which lists all crop protection products available to grape growers, their terms of use and status.

“In my role at WineGB, I endeavour to help get plant protection approvals for use within the vineyard and I keep members updated with new developments in legislation,” said Chris. “As the vineyard area in the UK increases it is getting slightly easier to secure approval for use in grapevines. Manufacturers and distributors see opportunity in this growing sector and are therefore more willing to invest in acquiring the UK specific data CRD needs to get a product through the approval system.”

Once in place, EAMUs last as long as the UK approval lasts, but as the off-label process is often tricky and time consuming, to avoid this, Hutchinsons is currently in discussions with companies about getting full label approvals for products.

While a lot of growers feel that there are only a small number of chemicals available in their arsenal, and these are mostly only available on EAMUs, there are also an increasing number of growers looking to move away from traditional chemistry altogether.

“We need to have a robust enough toolkit to cope effectively with disease and pest pressures but we also need to deliver the crop without any unnecessary or unforeseen consequences to the wider environment,” said Mike. “A lot of people coming into viticulture are keen to reduce the amount of chemicals and pesticides and we sympathise with growers who want to do the right thing and want to be as soft as possible when it comes to crop protection. We have been actively trying to develop biorationals, non-pesticidal crop protection, and crop health strengthening products. We are entering a very exciting new era where there will be a lot of opportunity to manage the spray programme with softer materials which don’t have some of the same concerns which growers have about conventional chemistry.”

Now on offer to growers looking to adopt a more holistic approach is a range of products including: biostimulants, which help the plant to strengthen its immune system to resist attack; biologically derived products, which attack pests and diseases; and physical products such as netting to prevent birds, and biofilm to better manage weeds.

Having studied the environment for his Masters degree, Rob is very passionate about sustainability and believes that the key to this is not for the UK viticulture sector to stop spraying but to find better, softer ways to increase in yields and keep fruit healthy until harvest.

“Sustainability boils down to efficiency of resource use and one of the resources we utilise is land,” said Rob. “If you take land away to plant a vineyard, and you only produce one tonne per acre, then that is a grotesquely inefficient use of a resource. When we are talking about sustainability and minimising environmental impact, we should all be aiming to grow three tonnes per acre. The first way to do this is with good nutrition. A healthy plant is more resistant and there are plenty of proven links between disease and nutrition, such as the impact calcium feeding has on reducing botrytis susceptibility. Then there are new materials, which can switch on the plant’s own defence system.”

The idea that a plant can be forced to trigger its own defence mechanisms against a disease might seem like something out of a science fiction novel. This concept is not new and has been talked about in woolly terms for years. Today, however, the science is catching up and more proven products are making their way on to the shelves, with one key example being the biofungicide FytoSave®.

An efficient and sustainable solution against powdery mildew gets to work when the active substance in FytoSave is recognised by membrane receptors of the plant cell. Once detected, a biochemical signal is spread throughout the plant which sets off different defence mechanisms. As everything is happening within the plant, this also means that FytoSave is unaffected by rain.

“There is also a new product called CBL which contains flavonoids derived from orange,” said Rob. “These appear to switch on the plant’s immune system as well as affecting the roots, helping them to pick up nutrients from the soil. In using a programme of CBL application, growers can improve the health and vigour of the plant, by improving the plant’s access to nutrients in the soil. It is also thought to act against powdery mildew as during trials, Angela Berry at NIAB EMR found lower levels of powdery mildew where CBL had been used.”

New technology

Developments are not just taking place within crop protection sprays; Hutchinsons has seen much success with garlic paints, which seem to do just as good a job at sealing pruning cuts as manufactured wound protectors, and the firm is now offering bio-degradable films to protect against weeds.

“The biofilm has a lifespan of around 18 months to two years before it degrades into starch,” said Chris. “When used among newly planted vines it will supresses the weeds allowing the vines to better establish without competition which can set them back in the early years. When the biofilm does break down, the vineyard is left with a lovely soil surface with which growers can sow wild flower seed, fertiliser, or whatever is best for their site.”

The team is also able to help growers adapt to new technologies, such as weather stations, where the outputs can raise as many questions for growers as they answer.

“There is little point harvesting weather data if you don’t know what it means,” said Rob. “We will often sit down with growers and can help them to work out what the weather station is telling them. By turning that information into knowledge we can then inform strategy. I see a lot of Pessel units in vineyards and Pessel UK has recently launched a system called iMETOS LoRAIN. This system acts a bit like Wi-Fi and unlocks the ability to deploy a range of sensors around the vineyard. These sensors can include relatively cheap weather stations which generate enough data to drive a good disease forecasting model, and because they are relatively inexpensive, growers can have them situated in every shady hollow, or hot spot, or corner of every vineyard. It can help to provide intelligence of what is going on in the vineyard and we think that this will help many growers to improve the job they are already doing.”

Finding new suppliers

Many essential products, such as the bio-degradable bio-film to protect against weeds, have been carefully researched and sourced by Hutchinsons’ sundries manager Chris William.

Based from the firm’s Canterbury depot, Chris joined the team 18 months ago and has been drawing on his 26 years’ experience within the horticultural sector to build and develop an offering of 400 products. Supporting viticulturists throughout the entire growing season, the range encompasses everything from harvesting scissors, to metal posts, wires and clips, pruning secateurs and tying down wire.

“For decades Hutchinsons has been well-known for providing quality advice and now we are also able to provide quality tools which vineyard managers need to grow profitable crops,” said Chris. “I have been finding new suppliers from across the globe and we have been slowly expanding our offering. While the range will continue to grow to meet growers’ demands, we will release a catalogue in early 2020 detailing everything we can supply.”

As well as the launch of a comprehensive catalogue, the sundries team is also trialling a Spanish manufactured set of electronic secateurs and is expecting to have these available for the 2020 pruning season.

“We have a good relationship with Altuna and its mechanical pruners are certainly performing well in the field,” said Chris. “Looking at the battery life, comfort and usability, the battery-operated backpack system is showing good results across the board.”

Currently growers can purchase and collect a range of sundries from the Canterbury, Ledbury and Marden depots and those further afield can take advantage of Hutchinsons’ own fleet of delivery vehicles.

“We aim to offer a more customised service than the larger suppliers and can deal with vineyards and orders of all sizes,” said Chris. “If a grower needs to replace a few posts, or wants to plant just a couple of rows, we are here to help. Equally, if a grower needs something urgently, depending on the product, we can respond rapidly and can use our own vehicles to get products shipped overnight.”

Practical box solution

The support available to growers from the Hutchinsons team does not stop once the grapes have been harvested. Its subsidiary company Produce Packaging can supply wine producers with a full range of recyclable, attractive and practical boxes.

Based from its head office in Marden, Kent, Produce Packaging has been supplying fruit growers in the South East with recyclable, biodegradable and compostable packaging specifically designed for the fresh food industry for many decades.

In 1993 Hutchinsons purchased Produce Packaging. As well as helping the East Anglian agronomy company to expand its reach into the ‘Garden of England’, there was an appealing synergy between the two firms and Hutchinsons was finally able to offer crop packaging solutions to its growers in the East Anglian area and beyond.

Distributed nationwide from its four depots, Produce Packaging now also provides English and Welsh wine producers with one, two, three, six and 12 bottle boxes. Having various manufacturing partners means that the team can create bespoke boxes with windows, inserts and dividers.

“Concepts are only limited by the producers’ imagination as we are here to translate that into a feasible and practical box solution,” said Jeremy Sharp of Produce Packaging. “We have decades of experience in making cases and boxes for fruit growers so they can transport and display their fresh produce. As vineyards were becoming increasingly prevalent in our home territory, Kent, it seemed natural for Produce Packaging to extend its offering to the viticulture industry and to offer a full range of branded and transportable wine bottle boxes and gift packs to English and Welsh wine producers.”

Branded boxes range in material from single layer brown corrugate, normally used for transit, to solid board material, which can be used for elaborate designs and prints, including varnishes, to give that perfect presentation. There is also the option to produce premium printed wooded boxes. These are a step up from anything which can be produced in cardboard and are aimed at producers of premium wines which require a premium presentation.

“The quality of the box is normally determined by the purpose of the case,” said Jeremy. “If enhancing a brand, it needs to be attractive and convey the qualities of the producer, or if it is simply for delivery it needs to be practical. These are not mutually exclusive of course.”

With sustainability hot on the agenda, all Produce Packaging’s boxes are made from 100% recycled materials and even if you are having varnishes, embossing or gold leaf as part of the design, all boxes are 100% recyclable.

“As long as producers are not wanting their boxes to be waterproofed with polythene laminate, all our boxes, from the plainer transit options to the elaborate and colourful gift packs, will be fully recyclable,” said Jeremy. “As well as the boxes, the inserts which protect the bottles are made from a moulded fibre, paper pulp. This pulp is made from recycled sources and can be recycled too, unlike polystyrene chips or inflatable pockets.”

Regardless of which sector you are operating in, branding can be the difference between an easily forgotten product and one which is sought out time and time again.

“If a customer has purchased from a specific brand, they will be expecting their package to represent that brand,” said Jeremy. “However, producers often worry about wine packages going missing when being delivered by a courier. A non-descript brown box can alleviate the external interest, but inside that plain transit packaging you still need to have quality brand packaging which the customer is expecting to see. Those shipping individual bottles via couriers, will also need to think about the level of protection the packaging offers. Our moulded fibre inserts completely envelop the bottle and we can also work with producers to do an entirely bespoke insert.”

With a presence in all the major winegrowing regions of the UK, if a producer has an idea and wants to talk face to face, Produce Packaging have local representatives which can visit the vineyard. Alternatively, producers can call in to one of the offices or the team can work entirely via email. From concept to delivery, the process can take as little as six weeks, depending on how long it takes for the artwork and design to be finalised.

Hutchinsons Ltd

www.hlhltd.co.uk

rob.saunders@hlhltd.co.uk | 07879 694520

chris.cooper@hlhltd.co.uk | 07899 978207