The term effluent can quickly take the romance and glamour out of winemaking.

It takes a lot of water to produce wine and dealing with the wastewater from a winery is probably one of the biggest challenges – and nightmares – for wineries around the world. There can be substantial capital costs involved – but dire financial consequences for not getting it right. Vineyard looks at some of the systems being used in UK wineries.

Wastewater, or effluent, from the winery is due to cleaning the fermentation tanks and other processing equipment used in winemaking. It is not an obvious pollutant, but it can contain sugars, yeasts, organic acids, alcohols, cleaning chemicals and solids from juice or wine lees. These can all have an impact on the environment due to their requisite for oxygen to breakdown. The requirement can be measured and is known as its BOD (biochemical oxygen demand) and COD (chemical oxygen demand). The aim of a wastewater processing system is to reduce the BOD and COD levels to within acceptable parameters so that the water is able to be recycled or to join the waterways.

A winery needs to manage its wastewater effectively from both a legal and environmental perspective. In addition, reducing wastewater through efficiency of water consumption is an important aspect of many wineries’ sustainability policies. There are several options for handling wastewater and the most suitable system will depend on the winery design, the site, processing capacity, budget, proximity to mains drainage and local water authority regulations.

Monitoring water use in the winery and setting targets for reduction and recycling will not only reduce the load on the wastewater handling system, but also save on the water bill. Wineries can use a range of methods to reduce water, including steam for cleaning, hose guns that avoid leaks, tanks and other equipment with CIP (clean in place) systems,floor scrubbers, using recycled water for first rinse of items such as picking crates and – crucially – cellar team buy-in and training.

Bio-Bubble

Off the Line vineyard, in East Sussex, are in a rural location, so not on mains drainage, and have installed a Bio-Bubble system. When building their winery, owners Kristina Studzinski and Ann-Marie Tylan looked at all the different options. “As I am an ex-lawyer I first looked into the legislation and could see that winery wastewater is definitely categorised as trade effluent and needs to be dealt with appropriately. I think it would be a mistake for any winery not to consider its wastewater as trade effluent,” explained Kristina. “We looked at reed beds, but it seems that these do not work well in our climate with wet winters and often dry summers. We also looked at holding tanks and soakaways, but we decided on the Bio-Bubble. Although initially quite expensive we decided that it was worth the investment, as it avoids the costs of having waste tankered away. Importantly for us its more ethical and fits with our sustainability policy – it will pay for itself over time.”

The Bio-Bubble also takes the domestic effluent from the winery’s onsite toilet block and Kristina explains that “the domestic sewage is in fact important for the functioning of the Bio-Bubble in its treatment of the winery wastewater which is nutrient poor, as this with the aeration helps the breakdown of solids. When we installed the system, we had to get some sludge from Ridgeview Estate’s Bio-Bubble tanks to get a population of the right bugs– a bit like a starter culture.”

Off the Line have installed the less expensive Bio-Bubble option with two above ground, rather than below ground, tanks. One is a reactor tank and the other is a holding tank, together able to handle 47,000 litres. “They are both open, and I can tell you there is no smell. They can also handle a heavy downpour of rain. Apparently, the sludge that builds up will not need emptying for decades. One advantage of the Bio-Bubble is that it can handle the lees, we don’t have to separate them, basically everything goes in. The system is on WiFi and monitored by the installers, Advanced Aeration. There is a sensor which controls the discharge from the first tank to the second tank automatically. Eventually clean water gets discharged into a ditch as ground water, it’s not harmful and we have a permit from the Environment Agency,” commented Kristina.

“I would sing the praises of Bio-Bubble, and this is an option for smaller wineries.

I would have never imagined it, but It is a talking point for our tours and tastings!” She smiled.

On mains drainage

Contract winery, Defined Wine, is on an agricultural estate, in Kent, with mains drainage. When setting up the winery, owner Henry Sugden, applied to the local water authority for permission to discharge the winery wastewater into the main. “However, harvest was approaching, and we hadn’t heard back, so we accepted that the most efficient method would be to install a holding tank and have it emptied regularly. Then, one week after we bought the tank, we received permission to discharge into the main,” commented Henry.

As the water from the Defined Wine winery was discharged into the main, the water authority carries out regular sampling and analysis. “An inspector came and the first sample, at the beginning of harvest was fine, but just before the second sampling, later in harvest, someone emptied a tank with lees – and this resulted in our trade effluent bill increasing over six-fold and a letter to do something about it.”

Defined Wine have now adapted the winery’s wastewater process and installed a system using connected settling and balancing tanks. “The first tank allows both the COD and BOD waste and sediment from the winery to settle, which can then be drawn off and disposed of separately. The residual effluent flows into the balancing tank, where we can test the pH, and other criteria, and adjust as necessary so that it is within our licence parameters and meets our obligations, before it is discharged in batches into the main drain. This is far more sustainable and is what we should have had from the beginning,” Henry added.

Defined Wine’s sustainability policy includes plans to minimise the amount of water used and to set up a rainwater harvesting system, which will be filtered. “We are also looking at installing a suitable soak-away system but will still use a collecting tank to settle our solids. With our system we minimise the impact on the environment, by ensuring that the effluent we discharge has been correctly balanced, as well as reducing the cost of tankering away waste water.”

“My advice to other wineries is to first check if you are connected to mains drainage and if so, contact the trade effluent department of your supplier. Our inspector has been extremely helpful and has provided great advice. However it took a long time to reach the right department and the right person, nearly nine months. You also have to make them understand that a winery is not like a brewery, that its peak time for wastewater and effluent is the once-a-year harvest and they need to ensure that they take samples that reflect this.”

Defined Wine tanks ready to go into position

Constructed wetlands

Itasca Wines and Penn Croft vineyard, based in Hampshire, are fortunate to be in a rural setting, surrounded by farmland and have the scope for a wetland system. Winemaker, Ben Smith, who has worked in many wine regions of the world, comments that, “wastewater is one of the biggest challenges in most wine regions, including New Zealand, as if you breach regulations you can be shut down. Over here, the Environment Agency are taking vineyards more seriously now, even small producers need to plan to handle wastewater responsibly.”

Simon Porter, farmer, conservation agriculturist, and one of the founders of Itasca, looked at the options for wastewater when planning the winery. “We contacted the water authority, but our local water plant did not have capacity and would have been overloaded at peak times. We didn’t like the idea of using tankers, as this doesn’t fit with our ethos and story – which is to be sustainable and care for the environment. We also looked at the Bio-Bubble, but it seemed too industrial for us, and expensive. We are fortunate that we own the farmland so a wetland system was an option we could consider.”

Simon contacted an organisation called Living Water who had worked with wineries in other countries. “They designed a system for us which basically consists of collection and holding tanks, straw bales to filter solids, and three constructed wetland or ‘cells’ in series with a planted soakaway. We felt that this would fit with our story, ethos, principles and our practice of conservation viticulture.”

Simon and his co-founder did a cost-benefit analysis. “When comparing to the cost of using tankers to remove the wastewater, we think the system will pay for itself in about two years. As after the initial capital cost of installation, there are minimal on-going costs, and the system is very low maintenance.”

Itasca have designed the winery so that all the water used both inside the winery, and outside from the crush pad and crate washing areas, drains into an underground collection tank. “All our drain sumps have stainless steel baskets to catch the larger solids for separation, which can then be composted. The underground tank has a float pump which discharges into a large, half million litre, above ground holding tank. We also have a Klargester septic tank from the toilet block and the liquid fraction from this is pumped to the first wetland,” explained Ben.

“We have designed our own aeration system for the above ground tank using two small compressors which inject air bubbles intermittently, via a dozen or so rubber diaphragms. The tank is open, so it collects rainwater, which helps with dilution. This holding tank acts as a buffer or dosing system and we only release the wastewater to the first wetland cell gradually, when needed. The water release needs to be managed to ensure an appropriate supply, so during wetter seasons we hold back water to ensure we have water to release into the wetland when it is drier. Also, it is better to leave the water in the tanks until the spring as the wetland system works using microbes, and these are more active when its warmer,” commented Simon.

Before the wastewater is discharged into the wetlands, it is first ‘dribbled’ through three large straw bales placed on a tray to filter out any sediment. “These bales also serve to add biological activity with the straw’s own microbes and bacteria. The outlet then discharges the wastewater to the first wetland cell. The straw will be changed each year and the spent straw used for compost,” added Simon.

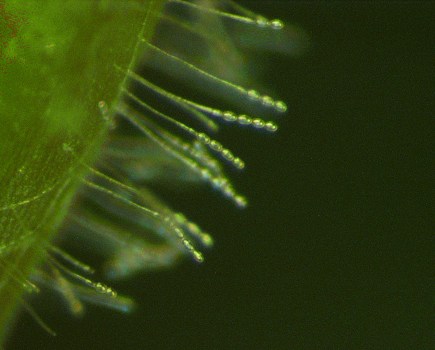

The wetland cells consist of three rectangular ponds, each with vinyl liners and about 100 tonnes of mixed size gravels. Simon explains, that “each wetland is planted with a selected range of species appropriate for the situation. There are 22 species that include rushes, sedges, water mint, canary grass as well as the common bullrush. These are natural species that match the ecology of wetland for best treating the type of effluent. Essentially, they are carrying out water purification – I describe it as similar to the work of the human kidney, Simon added.

The three wetland ponds are self-levelling, with the first overflowing into the second, then the third. The third pond has a pipe which then drains into a willow coppice, which creates a flood area. “The water is then gradually reduced by evapotranspiration by the willow as well as soaking into the chalk bedrock. Surprisingly the system is quite compact taking up an area of around 500m2, with each cell covering an area of about 125m2. When this system was designed, we submitted the plans to the Environment Agency – they really liked it and we received approval,” Simon commented.

Simon had the wastewater COD and BOD measured after harvest, and “the readings were 1235mg/L and 721g/L respectfully. However, two months later, after aeration the wastewater readings were reduced to 138 and 26. This is before the wastewater had entered the wetlands. We don’t know yet but believe both these measurements will be in single figures after. Our consultant from Living Water was very pleased as this means the wetlands do a lot less work,” said Simon and Ben added: “When selecting the chemicals that we need to use in the winery, I consider the downstream effect on the wetlands.”

The winery has been designed to limit water use, and Ben explains that “by regular monitoring we can put in measures to reduce water consumption. We use steam cleaning, pressure washing and all the hoses have guns so that they cannot be left on. We clean economically and work efficiently. Our target is to use five litres of water or less per litre of wine produced.”