Demystifying northern viticultural challenges

In part one of a two-part focus on viticulture in Yorkshire, Victoria Rose visits Laurel Vines in the hamlet of Aike, East Riding.

There is one enormous obstacle which is putting northern viticulturists and winemakers at a significant disadvantage in comparison to their southern counterparts

No, we’re not talking about site selection

Laurel Vines proves that it’s perfectly possible to find a south-facing, chalky slope which sits just 8-metres above sea level and is close to an estuary.

Nestled in the small hamlet of Aike, between the market towns of Beverley and Driffield, Laurel Farm was purchased by Ian and Ann Sargent in 2009. The ex-livestock farm’s derelict buildings had recently been renovated and the untouched pasture land provided an opportunity for Ian to develop a hobby outside his busy career as the owner of a large electricals firm.

“Designing electronic component systems is very intense, but I have never been one to just sit about. I needed to find something different to do in my downtime,” said Ian Sargent, founder of Laurel Vines and chair of WineGB’s regional group Midlands and North. “I had a strange notion that we could make wine here in Yorkshire. Surveys of the fields were carried out and everything was perfectly suited to a vineyard. We also checked drainage, pH levels and nutrient content as well as susceptibility to frost and wind. It ticked all the boxes.”

The chalk soils were prepared, the vines carefully selected and in April 2011 the first 2,000 Ortega, Rondo and Solaris were planted in a north-south alignment. Today the seven-acre vineyard is home to 12,000 vines, with varietals now also including Chardonnay, Madeline Angevine, Phoenix, Pinot meunier, Pinot noir, and Seyval blanc.

“The Champagne varieties were added three years ago,” said Jonathan Yeo, who assists Ian in the winery and manages the vineyard day-to-day with Adrian Scott. “We tested just two rows to see how they would grow up here and they did really well, so we planted more. They have taken slightly longer to come on than expected but we hope to get a full crop from them next year.”

To better protect the newer planting (which sits further down the vineyard slope) from the prevailing easterly wind, a windbreak has been established and the team has already noticed a significant difference in site temperature and vine growth. This, did however, create a barrier for the ground frost that previously rolled through the site, but after developing his own remote-controlled fan-driven frost system, to date, the vines have not suffered any frost related damage.

A year after planting, Laurel Vines was hit by some of the worst weather imaginable. Winter temperatures fell to -18°C, and long periods of rain caused flooding in spring and summer. This was not contained to Yorkshire; there is not one vineyard manager across the UK who will forget 2012, the year Nyetimber famously refused to make any wine.

“The climate might be one of our challenges, but it’s something other growers across the country have to deal with too,” said Jonathan. “I don’t think there is much difference between Yorkshire and the south, I think we can all produce good quality fruit.”

Picking is getting earlier each year. “Last year was a bit of an exception, but we started harvest around 20 September, which is the earliest we have ever been,” he said. “The 2018 season was just excellent overall. The quality of the fruit was impressive and we harvested around 17.5 tonnes of fruit, which is a record for us, although this does coincide with more vines coming online.”

While 2018 was glorious for growers nationwide, the wet and warm spells plaguing the end of the 2019 season have been equally challenging for vineyard managers, regardless of region.

“The crop level is around 3/4 the size of last year, the quality is good but not as brilliant,” said Jonathan. “With cooler weather during flowering, we have had some hens and chicks on the Rondo, but this is the first year we have seen it. We didn’t quite know what was wrong at first, because we are only used to seeing what we have seen before, but I believe other people have had similar issues too. There have been a lot of vineyards who have had real problems with the rain this year and Botrytis has been a big worry, but everything seems on track so far.”

Finding sufficient seasonal labour is not an issue

Despite there being some 20 vineyards spread across the county of Yorkshire, with more new enterprises due to be planted in 2020, the first misconception which the team at Laurel Vines deals with is the ingrained concept that it is simply impossible to grow vines this far north.

“One of the biggest things we notice is that the public always question how it is possible to have a vineyard in Aike,” said Adrian Scott. “Even people in the next village, will dispute that there is one planted because no one really expects to find a vineyard in Yorkshire. The industry is growing, but in this region especially there is a lot of surprise about English wine.”

The public’s persistent disbelief over the existence of vines in Yorkshire is not dampening the growing industry spirits, as once people do discover the vineyard, they quickly become thoroughly invested in the story.

These converted loyal supporters are often keen be involved too. Laurel Vines once again had people pestering for harvest dates to be released with many eager to sign up to be involved in this annual social and community event.

“Our picking days are always really well subscribed,” said Jonathan. “The vineyard started life as a hobby and Adrian and I both started volunteering here. That combined with the close-knit atmosphere in the village has meant that people have always wanted to come here to help. They enjoy it so much they tell their friends and family who all want to come along next year.”

Harvest is however an exception and through the rest of the year Laurel Vines is just a family operation. Ian and Rebekah, Ian’s daughter and Jonathan’s partner, both balance their time between the family’s electrical business and Laurel Vines, and Ian’s wife, Ann, and brother, Neil, also get involved when needed. On a day-to-day basis, the vineyard is managed predominantly by Jonathan and Adrian.

“With the increasing number of vines, it is becoming increasingly difficult to do everything ourselves,” said Jonathan. “We usually start pruning in December and aim to have everything finished in late March, but we are normally a bit behind. We do also have a SEND college group who come to the vineyard once a week in term time to help with jobs like tying down.”

Getting vineyard sundries and winery equipment delivered takes no more effort

Unlike most vineyards in the UK, Laurel Vines’ grapes only travel a few 100 yards to the winery. Not only does this help the business boast a low carbon footprint, it also makes it easier for the team to control the whole process too.

“As soon as it comes off the vine, fruit is in a tank within four hours,” said Jonathan. “The only time our wine leaves site is when it is sold. Ian likes to put his own stamp on everything he makes. We focus on producing single-varietal wines and always try to let the raw taste of the vineyard come through. We also use as little sulphur as possible.”

Alongside their vineyard duties, Jonathan and Adrian also play a key role in the winery. As everything is done on site, from the growing, to the winemaking, bottling and labelling, it is vital that every stage of the process is kept as simple and as time efficient as possible.

With this in mind, the team has recently taken delivery of a shiny new Massey Ferguson vineyard tractor, which is geared towards increased mechanisation in the vineyard. The winery has also been revamped and the new facilities, benefiting from significant investment, have been carefully designed and future-proofed by Ian.

“When we took delivery of the crossflow filtration system, we were told by the supplier Romfil that it is probably the only one north of the Watford Gap,” said Jonathan. “It has been a game-changer. We can be getting on with so many other jobs while it is running and the membrane filter has also made bottling more straightforward. Instead of having to change plate filters every few hours, we can bottle four varietals in four days and just rinse between. It can also run as fast as you can physically bottle and that has saved us a lot of time.”

Despite being miles away, there have never been any issues when it comes to working with suppliers. Four more variable capacity temperature-controlled tanks are imminently making their way from Speidel in Germany to Aike. Devon-based winery equipment supplier Vigo was instrumental in helping Ian to establish the winery and the crossflow filter manufacturer, Romil, also travelled from Devon to Yorkshire several times to ensure that the machine was correctly installed and that the team were well accustomed to operating it.

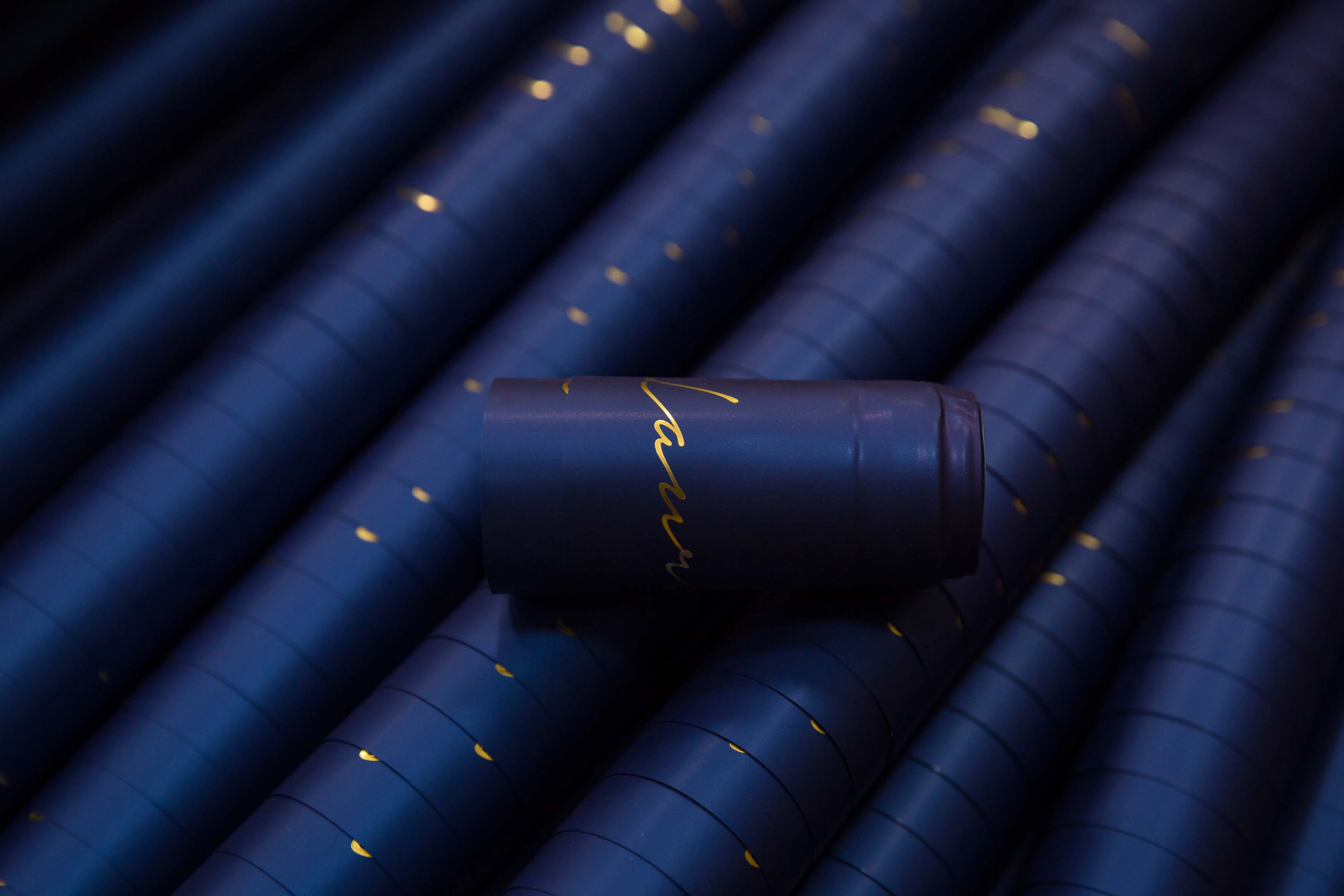

“We work with a big range of suppliers and don’t have many issues getting things here,” said Jonathan. “People seem to be more willing to work with us and it is getting quicker to order some items, such as corks and bottles. I think this is partially to do with our expansion – we now need 10,000 corks instead of 1,000 – and I think as there are more vineyards in Yorkshire, and with Ian’s involvement in WineGB, we do seem to be a bit more on the map.”

The wines are proving their worth too

Following the bumper harvest last year, Laurel Vines produced 16,500 bottles of its single-varietal blends. All of Ian’s wines have successfully been through the PGI scheme, have won numerous awards and have been sought out by skilled sommeliers of Michelin-starred restaurants.

Last year, for the second year in a row, Ian was awarded the trophy for the best commercial grower-winemaker of the year at the Mercian Vineyard Association (now called WineGB Midlands and North) annual awards and the estate’s 2017 Solaris, Ortega, Madeline Angevine and Phoenix wines all achieved silver, with a bronze for the 2017 Rondo rosé.

The estate has also just bottled its first still red. The 2016 vintage, a 100% Rondo, has been maturing in French oak and the result is a silky and bold fruit driven offering. There is also a 2017, 80% Rondo 20% Pinot noir blend, in production and the 2018 vintage, a 90% Rondo 10% Pinot noir blend, has just been transferred in to oak. It will spend six to eight months maturing before being bottled next year.

This vibrant selection of wines has certainly started to draw interest and support from the Yorkshire trade, but this isn’t just the local pub stocking a local wine for the sake of locality. Laurel Vines boast a number of high-end restaurants and Michelin-star graded outlets among its regular customers.

“We have received a lot of praise and support for our wines from the Pipe and Glass in Dalton, as well as Roots in York and the Black Swan at Oldstead,” said Ian. “Restaurants of this calibre will only take the wine if it is good enough. A few weeks ago, James and Tommy Banks, from Roots and the Black Swan, brought their entire team to the vineyard one afternoon. It is great for the people serving the wines to be able to say they have seen the vines and have tasted new vintages from barrel.”

There is certainly plenty of market space to share among the Yorkshire producers and encouragingly many of the Aike-producer’s trade customers are also keen to promote the estate’s wines by the glass. Allowing people to try a glass without having to commit to the whole bottle is proving fruitful and the team have noticed that trade customers who sell by the glass tend to order around three times more than those who only sell by the bottle.

If there is nothing stopping producers growing grapes, making quality wines or gaining recognition from Michelin-star restaurants, what then is putting northern viticulturists and winemakers at a significant disadvantage in comparison to their southern counterparts?

The main challenge northern producers face is education

There is just one wine education ‘centre of excellence’ in the UK. Its list of alumni is enviable, and few UK wine industry trailblazers have not graced its hallways at some point.

But its rural West Sussex location creates a logistical nightmare for those in the Midlands or North regions. It is nigh on impossible for any potential student to consider enrolling on its courses without having to also consider upping sticks. This is something which Jonathan learnt the hard way.

“I am still really interested in completing the Viticulture and Oenology BSc course at Plumpton College but I need to find a way which will enable me to carry on working here full time while studying,” said Jonathan. “We live in an age where technology should make distance learning more than possible, but I was still required to travel to Brighton once or twice a week. There was no compromise to be had and in the end the college was unable to accommodate a student this far north.”

Although the majority of the UK’s vines are located in the South East, there are people all over the country who want to learn more about grape growing and winemaking. Fortunately for the industry, the education conundrum has since become a subject which Laurel Vines’ owner, and chairman of WineGB Midlands and North, Ian Sargent has become increasingly determined to find a solution to.

“Education is the biggest factor holding the county’s wine industry back,” said Ian. “In my other business, I have meetings with people from all over the world. Communication is no longer the issue. Education should be available to all the UK’s wine regions, whether that is delivered via the internet, or perhaps from new wine centres.”

Looking to the future, Ian has had a number of positive meetings with the college and hopes that viticulture and oenology training and education opportunities, be that in the form of WineSkills workshops and or full degree courses, will soon be possible on a more equal regional and local scale.